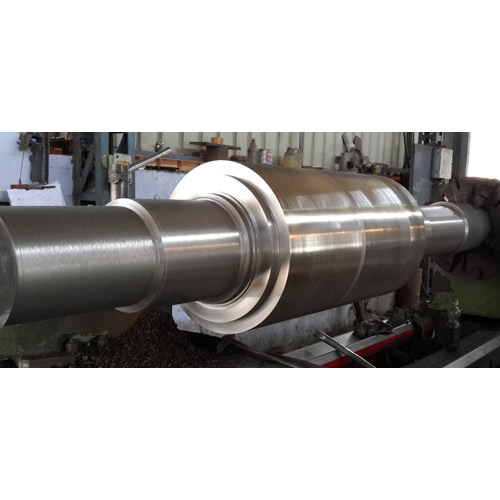

SGI Benatic Rolls

Price 10000 INR/ Piece

MOQ : 1 Unit

SGI Benatic Rolls Specification

- Capacity

- Customizable as per requirement

- Diameter

- 80 mm to 500 mm

- Material

- Mild Steel

- Dimensions

- Custom size available

- Technique

- Hot Rolled

- Standard

- Industrial Grade

- Belt Width

- 400 mm to 2200 mm

- Feature

- Long Service Life, Smooth Functioning, Rust Proof

- Maintenance

- Low Maintenance Requirement

- Application

- Conveyor System Support

- Coating

- Powder Coated or as Required

- Load Bearing Capacity

- Up to 2000 kg (Customizable)

- Surface Finish

- Polished

- Operating Temperature

- -20°C to 70°C

- Manufacturing Certification

- ISO 9001:2015 Certified

- Installation

- Easy and Quick Mounting

- Roller Type

- Carrying/Return Roller

- Color

- As per Client Specification

SGI Benatic Rolls Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Day

- Delivery Time

- 1 Months

- Main Export Market(s)

- Asia, Australia, South America, Western Europe, Middle East, Central America, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About SGI Benatic Rolls

Our SGI Benatic Rolls are composed mainly of pearlite with some cementite in the structure. They are much more stronger than cast iron rolls and other steel rolls. Our offered rolls are available in various hardness and composition for diverse application. The provided rolls are used for slabbing and blooming mills. They are also used for roughing, intermediate and finishing for rail and structural mils. In addition to this, the offered SGI Benatic Rolls perform well on strength, toughness and hot crack resistance.

Robust Design and Versatile Application

SGI Benatic Rolls provide unmatched durability and flexibility for conveyor system support. Featuring customizable dimensions and finishes, these rollers accommodate a broad spectrum of industry needs. Their robust construction ensures smooth, reliable operation even under demanding conditions, making them suitable for both carrying and return roller roles in industrial environments.

Long Service Life and Easy Installation

Engineered for longevity, SGI Benatic Rolls require minimal maintenance and are designed for quick and effortless mounting. Their rust-proof, industrial-grade finish further extends operational lifespan. Clients benefit from tailored solutions that conform to specific load, temperature, and color preferences, all while ensuring high standards of quality and safety.

FAQs of SGI Benatic Rolls:

Q: How do I install SGI Benatic Rolls in my conveyor system?

A: SGI Benatic Rolls are designed for easy and quick mounting, allowing users to install them without specialized tools or complex procedures. The rollers can be integrated directly as carrying or return rollers depending on your conveyor layout, minimizing downtime during setup.Q: What are the customization options available for these rollers?

A: You can customize SGI Benatic Rolls in terms of diameter (80 mm to 500 mm), belt width (400 mm to 2200 mm), load capacity (up to 2000 kg), coating, color, and overall dimensions. Specific client requirements can be accommodated to ensure compatibility with various industrial applications.Q: When should I consider replacing or upgrading my conveyor rollers?

A: Its advisable to replace or upgrade your conveyor rollers when you notice signs of wear, decreased performance, or if your operational requirements change. SGI Benatic Rolls offer a long service life and low maintenance needs, but routine inspections will ensure optimal functioning.Q: Where are SGI Benatic Rolls typically used?

A: These rollers are primarily used in industrial conveyor systems for supporting carrying or return operations. Their design is suitable for a wide range of sectors, including material handling, manufacturing plants, and warehouses across India and beyond.Q: What benefits do SGI Benatic Rolls provide compared to standard rollers?

A: SGI Benatic Rolls offer superior load-bearing capacity, rust-proof surfaces, and smoother functioning. Clients benefit from easy installation, customizable sizing, long service life, and compliance with ISO 9001:2015 standards, ensuring both reliability and safety in industrial environments.Q: How does the powder coating or custom finish enhance the rollers performance?

A: The powder coating or tailored surface finish protects the rollers against corrosion and abrasion, ensuring rust-proof operation and extending their usability even under harsh working conditions. This contributes to consistent, trouble-free conveyor movement.Q: What is the maintenance process for SGI Benatic Rolls?

A: Maintenance requirements are minimal. Regular visual checks for any signs of mechanical wear or coating damage are sufficient. Due to their robust construction and rust-resistant finish, SGI Benatic Rolls remain operational with little intervention, maximizing productivity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Casting Rolls Category

Chill Roll Castings

Price 10000 INR / Piece

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : cast Iron

Cracker Rolls

Price 10000 INR / Piece

Minimum Order Quantity : 1 Unit

Usage : oil seed extraction plants, feedlots and breakfast cereals industry

Material : Cast Iron

Nodular Cast Iron Rolls

Price 10000 INR / Piece

Minimum Order Quantity : 1 Unit

Usage : printing, textile, material handling

Material : Cast Iron

Centrifugal Castings Rings

Price 10000 INR / Piece

Minimum Order Quantity : 1 Unit

Usage : Industrial

Material : Steel

|

INDIA FACTORY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry